Factory line IOT system

Build intelligent factories and promote enterprise upgrading

Equipment interconnection

Equipment data collection

Equipment data standardization

Remote Maintenance of equipment

Production line data visualization

Production line data analysis

On the basis of digital factory, with the purpose of optimizing production process and business operation, intelligent factory uses Internet of Things technology and monitoring technology to strengthen information management services, improve the controllability of production process, reduce manual intervention of production line, reasonably plan scheduling, realize information unification, group unified monitoring, realize product life cycle and spare parts management, and improve the intelligent degree of manufacturing factory, Reduce operation and maintenance costs and promote industrial upgrading of enterprises.

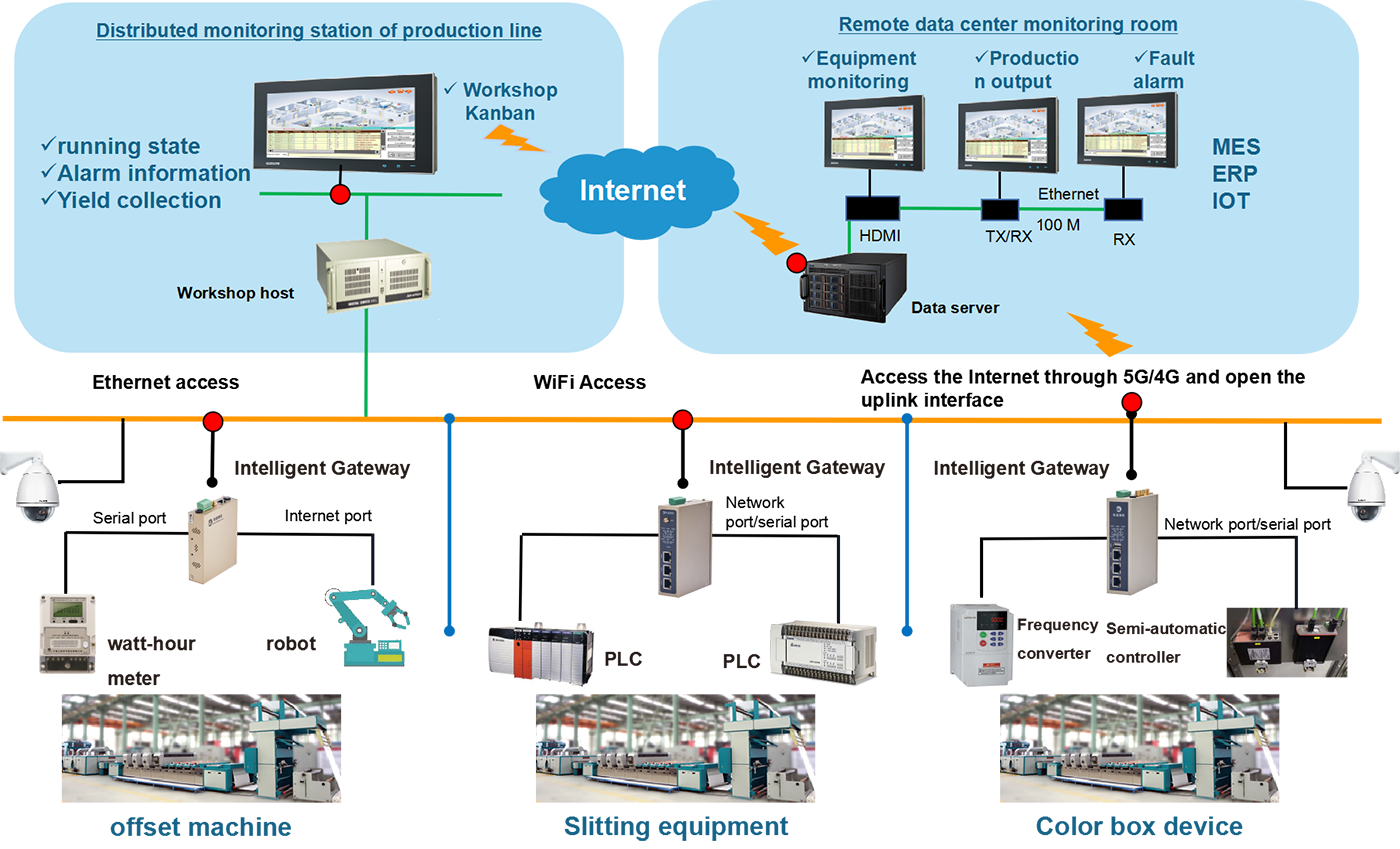

WideIOT Integration of industrialization and industrialization and edge computing gateway are used to collect the data of industrial equipment in the factory shop floor, and the edge computing and data standardization are realized in the gateway, and then the data are uploaded to the shop floor Kanban and the group Internet of Things cloud platform. After cleaning, computing, storing and analyzing the data, the real-time status and production status of factory equipment can be displayed through visual reports and industrial flow charts, so as to improve the intelligence of manufacturing plants, reduce operation and maintenance costs, and promote enterprise upgrading.

Internet of Everything

Intelligent Collection

Edge Computing

Cloud Application

Equipment interconnection

Realize networking of factory sensors, electricity meters, PLC controllers, industrial machine tools, industrial robots and other equipment

Equipment data collection

Collect real-time status, operation status, production status and other data of plant production line equipment

Equipment data standardization

Standardize equipment data to facilitate data interchange and call of MES and ERP systems

Remote Maintenance of equipment

Fault alarm, patrol maintenance, equipment maintenance, predictive maintenance, etc., to ensure the sound operation and service life of equipment.

Production line data visualization

Large data screen, visual display, display system operation, shift arrangement, process flow monitoring, etc

Production line data analysis

Multidimensional integration, analysis and application of production line data to provide big data support for intelligent factories and facilitate digital management and operation

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

Industrial DTU

WideIOT·WD Data Terminal mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

Wtunnel

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.

click to view detail>>

-

WCloud

WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.

click to view detail>>

-

WLink

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD Data Terminal mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD Data Terminal mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.click to view detail>>

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.click to view detail>> WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.click to view detail>>

WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.click to view detail>> WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.click to view detail>>

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.click to view detail>>

Go Top

Go Top